AARVI MARKETING P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to AARVI MARKETING P.LTD.

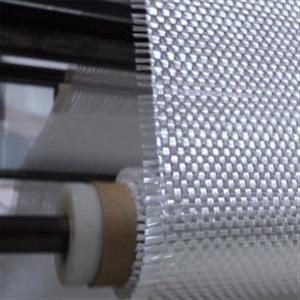

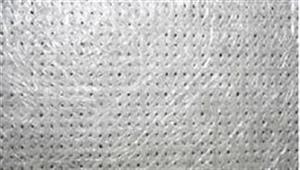

Fiber Glass Cloth

It’s a closely-woven cloth fabricated of glass fibers; often used as a finishing jacket over thermal insulation for piping.

General Description: Woven fiberglass cloths are very common for marine & composite construction and repair. Light weight cloths tend to provide a smooth finish and are excellent for producing a waterproofing layer over wood or other surfaces when combined with the appropriate resin. Heavier cloths will provide greater strength and overall rigidity. All of our fiberglass cloths are compatible for use with our polyester resins, epoxy resins or vinyl ester resin.

The versatility of glass as a fiber makes it a unique industrial textile material. Fiber glass in fabric form offers an excellent combination of properties from high strength to fire resistance. Wide ranges of yarn sizes and weave patterns provide huge number of design potential allowing the end user to choose the best combination for material performance, economics and product flexibility.

Properties of Fiber Glass Cloth:

· Dimensional Stability: Fiber glass is a dimensionally stable engineering material. Fiber glass does not stretch or shrink after exposure to extremely high or low temperatures. The maximum elongation for "E" glass at break is 4.8% with a 100% elastic recovery when stressed close to its point of rupture.

· Moisture Resistance: Glass fibers do not absorb moisture, and do not change physically or chemically when exposed to water.

· High Strength: the high strength-to-weight ratio of fiber glass makes it a superior material in applications where high strength and minimum weight are required. In textile form, this strength can be unidirectional or bidirectional, allowing flexibility in design and cost.

· Fire Resistance: Fiber glass is an inorganic material and will not burn or support combustion. It retains approximately 25% of its initial strength at 1000 deg F (540 deg C).

· Chemical Resistance: most chemicals have little or no effect on glass fiber. The inorganic glass textile fibers will not mildew, rot or deterioriate. Glass fibers are affected by hydrofluoric, hot phosphoric acids, and strong alkaline substances.

· Electrical Properties: fiber glass is an excellent material for electrical insulation. The combination of properties such as low moisture absorption, high strength, heat resistance and low dielectric constant makes fiber glass fabrics ideal as reinforcement for printed circuit boards and insulating varnishes.

· Thermal Conductivity: Low coefficients of thermal expansion combined with high thermal conductivity properties make glass fabric a dimensionally stable material that rapidly dissipates heat as compared to asbestos and organic fibers.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.